|

|

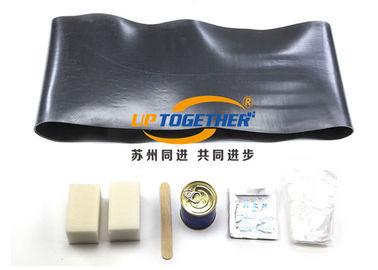

Tubular 3PE Heat Shrinkable Sleeve WSS60 Series Φ219 * 500MM Black Color

Product Details:

Payment & Shipping Terms:

|

| Material: | PE | Width: | 250-680mm |

|---|---|---|---|

| Base Thickness: | 1.0-1.5mm | Plastic Modling Type: | Extruding |

| ID: | 50-2200mm | Shrink Ratio: | >50% |

| Adhesive Thickness: | 0.8-2.0mm | ||

| High Light: | heat shrink tubing wrap sleeves,electrical shrink wrap sleeves |

||

3PE heat shrinkable tubular sleeves for pipeline TS , Black ,WSS60Φ219x500-1.2/1.0mm

1. Product Introduction

TS series of 3PE heat shrinkable tubular sleeves are consist of a radiation cross-linked heat shrinkable backing coated on the inside with a heat activated adhesive. It is easier to install as compared to the wraparound design.While the modified polyethylene material of the backing offers superior mechanical protection, the specially formulated adhesive offers excellent corrosion protection under demanding conditions.Used in conjunction with the proprietary epoxy primer,the 3 layer system is the choice of discerning clients who need long term corrosion protection.

![]()

2. Technical Parameter

| Temperature Degree | TS60 | TS80 |

| Max Operating Temperature | 60℃ | 80℃ |

| Suitable Coating | PE,FBE,PP | PE,FBE,PP |

| Preheat Temperature to Steel | 75℃ | 85℃ |

| Rust Cleaning Degree | Sa2.5,St3.0 | Sa2.5,St3.0 |

| Property | Test Method | TS60 | TS80 | |

| Epoxy Primer | ||||

| Solid Content(%) | ASTM D6980 | 99.5 | 99.5 | |

| Cathodic Disbonding (65℃,48h) (mm) | DIN EN12068 | 8 | 8 | |

| Backing | ||||

| Tensile Strength (psi) | ASTM D638 | 2700 | 2900 | |

| Elongation (%) | ASTM D638 | 500 | 500 | |

| Dielectric (KV/mm) | ASTM D149 | 25 | 25 | |

| Volume Resistance (Ω.cm) | ASTM D257 | 1.0x1016 | 1.0x1016 | |

| Water Proof (%) (WT) | ASTM D570 | <0.1 | <0.1 | |

| Adhesive | ||||

| Softening Point(℃) | ASTM E28 | 105 | 112 | |

| Lap Shear (N/cm2 )@23℃ | ASTM D1002 | 200 | 400 | |

| Lap Shear (N/cm2 )@80℃ | DIN EN12068 | 20 | 11 | |

| Installed Product | ||||

| Peel Strength (N/cm)@23℃ | DIN EN12068 | 65 | 70 | |

| Impact Resistance(J) | DIN EN12068 | >15 | >15 | |

| Cathodic Disbonding (mm rad) | DIN EN12068 | <12 | <15 | |

| Resistance to thermal Aging | DIN EN12068 | 100d @60℃ | 100d @80℃ | |

| Tensile Strength Ratio | DIN EN12068 | 0.9 | 0.9 | |

| Elongation Ratio | DIN EN12068 | 0.9 | 0.8 | |

Please contact us for more details

3. Specification Packaging

| Pipe Size | Pipe OD | Sleeve OD | Epoxy Primer | ||

| Part A | Part B | ||||

| DN | Inch | (mm) | (mm) | (gms) | (gms) |

| 100 | 4 | 114 | 140 | 39 | 20 |

| 125 | 5 | 141 | 170 | 48 | 24 |

| 150 | 6 | 168 | 198 | 54 | 27 |

| 200 | 8 | 219 | 252 | 69 | 35 |

| 250 | 10 | 273 | 308 | 84 | 42 |

| 300 | 12 | 325 | 360 | 98 | 49 |

| 350 | 14 | 355 | 393 | 106 | 53 |

| 400 | 16 | 406 | 446 | 120 | 60 |

| 450 | 18 | 457 | 497 | 36 | 68 |

| 500 | 20 | 508 | 550 | 150 | 75 |

| 600 | 24 | 610 | 655 | 178 | 89 |

| 700 | 28 | 711 | 755 | 206 | 103 |

| 800 | 32 | 813 | 860 | 250 | 125 |

| 900 | 36 | 914 | 960 | 280 | 140 |

| 1000 | 40 | 1016 | 1066 | 388 | 144 |

Please contact us for other OD details

Purchase Guide

Example: TS60Φ219x500-1.2/1.0 (mm)

1, TS:Product code,measure unit:PC.

2, 60:Operating Temperature.

3, Φ219:Suitable steel OD,range: Φ50-2200mm.

4, 500:Sleeve width,range 250-680mm.

5, 1.2:Backing thickness,range:1.0-1.5mm.

6, 1 .0:Adhesive thickness,range:0.8-2.0mm.

TS60& TS80 sleeves can be delivered as kits. Each factory assembled kit will consist of one sleeve, suitable for a particular pipe size and pre-measured quantities of solvent free,two-part epoxy primer. In addition, the kits will also contain small tools like mixing stick,application pads and gloves. The epoxy primer kits can be ordered separately.

4. Ordering Information

Packing

1. By diffrent cartons and plastic pallents.

2. Anonymous packing is available.

3. OEM packing is available.

4. Do as customer's requirements.

Delivery

1. Our factory is nearby Shanghai.

2. Other seaport is acceptable.

3. Do as customer's requirements.

Contact Person: Jimmy

-

Bulk Roll Heat Shrinkable Sleeve For Pipeline Anti Corrosion Coating WSS80

-

30M Length Heat Shrink Sleeve , Anti Corrosion Shrink Wrap Sleeves WSS60

-

PE Plastic Heat Shrinkable Sleeve 50 - 1000MM Width 50℃ Operating WSS80

-

Black / Yellow Heat Shrink Tubing Wrap Sleeves Equal To WLNN / WLON

-

WSS Mastic Wraparound Heat Shrinkable Sleeve Inner Diameter 50 - 3200MM , Material PE

-

Black Waterproof Heat Shrink Sleeving , Wrap Around Heat Shrink Plastic Sleeve