|

|

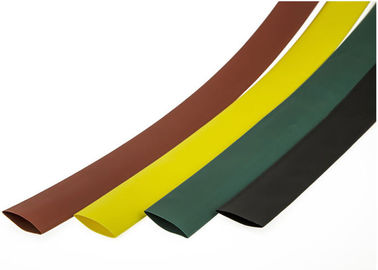

Halogen Free Colorful Thin Wall Heat Shrink Tubing 125 ℃ Fully Shrink

Product Details:

Payment & Shipping Terms:

|

| Rated Voltage: | 600V | Application: | High Temperature |

|---|---|---|---|

| Wall: | Thin Wall | Color: | Black,White,Yelllow,Red,Green,Clear,Grey,Brown |

| Type: | Insulation Sleeving, Flame Resisitance,Halogen Free | Certification: | SGS |

| Highlight: | heat shrink plastic tubing,heat shrink wrap tubing |

||

Halogen - free Heat Shrink Tube , Thin Wall Tube , HFDRS , Black , White , Yelllow

1. Product Introduction

HFDRS halogen-free tube is a heat shrink tubing with thin wall that are made of polymer material.

This heat shrink tubing is widely used to the cable and wire insulation and protection.

The material is Rohs approval and without Halogen material.

This heat shrink tubing tube is not flame resistance,but it is low smoke generation if burning

Shrink ratio is 2:1,

Continuous operating temperature:-55 ℃ to 125 ℃

Fully shrink temperature:12 5 ℃

2. Technical Parameter

| Property | Test Method | Result |

| Tensile Strength | ASTM D638 | 12 N/mm2 |

| Elongation | ASTM D638 | 300% |

| Heat Shock@250℃/30’ | ASTM D2671 | No Cracking .No Flow |

| Cold Blend@-30℃ | ASTM D2671 | No Cracking |

| Dielectric Strength | ASTM D149 | 15kv/mm |

| Voltage Withstand | @2.5kv for 60 sec | No breakdown |

| Volume Resistivity | ASTM D257 | 1x1014Ω.cm |

| Longitudinal Change | ASTM D2671 | Inside +/- 5% |

3. Specification Packing

2:1 Ratio

| Size | Before Applied (mm) | After Applied (mm) | Package | ||

| (mm) | Internal Diameter |

Wall Thickness |

Internal Diameter |

Wall Thickness |

(M/Spool) |

| Ø3.0/1.5 | 3.5±0.2 | 0.18±0.05 | ≤1.5 | 0.35±0.05 | 200 |

| Ø3.5/1.75 | 4.0±0.2 | 0.18±0.05 | ≤1.75 | 0.40±0.05 | 200 |

| Ø4.0/2.0 | 4.5±0.2 | 0.20±0.05 | ≤2.0 | 0.40±0.05 | 100 |

| Ø5.0/2.5 | 5.5±0.3 | 0.20±0.08 | ≤2.5 | 0.40±0.08 | 100 |

| Ø6.0/3.0 | 6.5±0.3 | 0.20±0.08 | ≤3.0 | 0.40±0.08 | 100 |

| Ø7.0/3.5 | 7.5±0.3 | 0.20±0.08 | ≤3.5 | 0.42±0.08 | 100 |

| Ø8.0/4.0 | 8.5±0.3 | 0.20±0.08 | ≤4.0 | 0.42±0.08 | 100 |

| Ø9.0/4.5 | 9.6±0.3 | 0.22±0.08 | ≤4.5 | 0.45±0.08 | 100 |

| Ø10.0/5.0 | 10.6±0.4 | 0.22±0.08 | ≤5.0 | 0.45±0.08 | 100 |

| Ø11.0/5.5 | 11.6±0.4 | 0.22±0.10 | ≤5.5 | 0.45±0.10 | 100 |

| Ø12.0/6.0 | 12.6±0.4 | 0.22±0.10 | ≤6.0 | 0.45±0.10 | 100 |

| Ø13.0/6.5 | 13.6±0.4 | 0.23±0.10 | ≤6.5 | 0.46±0.10 | 100 |

| Ø14.0/7.0 | 14.6±0.4 | 0.23±0.10 | ≤7.0 | 0.46±0.10 | 100 |

| Ø15.0/7.5 | 15.6±0.5 | 0.23±0.10 | ≤7.5 | 0.46±0.10 | 100 |

| Ø16.0/8.0 | 16.6±0.5 | 0.25±0.10 | ≤8.0 | 0.50±0.10 | 100 |

| Ø18.0/9.0 | 18.6±0.5 | 0.25±0.10 | ≤9.0 | 0.55±0.10 | 100 |

| Ø20.0/10.0 | 20.6±0.6 | 0.25±0.10 | ≤10.0 | 0.55±0.10 | 100 |

| Ø22.0/11.0 | 22.6±0.6 | 0.28±0.10 | ≤11.0 | 0.60±0.10 | 100 |

| Ø25.0/12.0 | 25.6±0.6 | 0.30±0.10 | ≤12.0 | 0.65±0.10 | 25 |

| Ø28.0/14.0 | 28.8±0.8 | 0.30±0.10 | ≤14.0 | 0.65±0.10 | 25 |

| Ø30.0/15.0 | 30.8±0.8 | 0.33±0.10 | ≤15.0 | 0.70±0.10 | 25 |

| Ø35.0/17.5 | 36.0±1.0 | 0.35±0.10 | ≤17.5 | 0.75±0.10 | 25 |

| Ø40.0/20.0 | 41.0±1.0 | 0.35±0.10 | ≤20.0 | 0.75±0.10 | 25 |

| Ø50.0/25.0 | 51.0±1.0 | 0.40±0.10 | ≤25.0 | 0.80±0.10 | 25 |

| Ø60.0/30.0 | 61.0±1.0 | 0.40±0.10 | ≤30.0 | 0.80±0.10 | 25 |

| Ø70.0/35.0 | 71.0±1.0 | 0.40±0.10 | ≤35.0 | 0.80±0.10 | 25 |

| Ø80.0/40.0 | 81.0±2.0 | 0.45±0.10 | ≤40.0 | 0.90±0.10 | 25 |

| Ø90.0/45.0 | 91.0±2.0 | 0.45±0.10 | ≤45.0 | 0.90±0.10 | 25 |

| Ø100.0/50.0 | 102.0±2.0 | 0.50±0.10 | ≤50.0 | 1.0±0.20 | 25 |

| Ø120.0/60.0 | 122.0±2.0 | 0.50±0.10 | ≤60.0 | 1.0±0.20 | 25 |

| Ø150.0/75.0 | 152.0±2.0 | 0.50±0.10 | ≤75.0 | 1.0±0.20 | 25 |

4. Ordering Information

Packing

1By diffrent cartons and plastic pallents.

2.Anonymous packing is available.

3.OEM packing is available.

4.Do as customer's requirements.

Delivery

1.Our factory is nearby Shanghai.

2.Other seaport is acceptable.

3.Do as customer's requirements.

5. Application Case

![]()

![]()

Contact Person: Jimmy

-

ROHS Thin Wall Flexible Tubing Polyolefin Heat Shrinkable For Cable Insulation

-

Low Temperature Heat Shrink Tubing , Cable Protection Thin Wall Plastic Tube

-

Voltage Class 0.6kV 2/1 Ratio Thin Wall Heat Shrink Tubing For Insulation Protection

-

90PCS Colorful Polyolefin Heat Shrink Tubing For Mobile Phone Data Cable Or Wire Repair

-

1kV Colored Thin Wall Heat Shrink Tubing Distinguish Use Length Of Customers

-

Grey Transparent Polyolefin Heat Shrinkable Tubing For Wires And Electrical Insulation